Screw press is a kind of processing equipment with constant energy (E=1/2Jω2). According to the types of power transmission, there are friction press (first generation), electric screw press (second generation) and servo direct drive screw press (third generation).

1. Friction press: the motor changes the flywheel rotation direction through the friction plate and control cylinder.

Transmission efficiency is only about 60%, high energy consumption equipment; strike energy can not be accurately controlled, poor safety, belongs to obsolete products.

2. Electric screw press: the motor changes the flywheel rotation direction through gear or belt drive.

At present, there are two main schemes for the domestic electric screw press: switched reluctance motor drive system and AC asynchronous motor variable frequency drive system.

1) When switched reluctance motor and steel gear drive are adopted:

The motor torque ripple is large (average torque ripple is 70-100%), the speed control is not accurate, the impact energy is not accurate, and the fluctuation is large.

The noise of steel gear transmission is large and the wear of flywheel tooth surface is large.

2) When using asynchronous motor and bakelite gear drive mode:

The weakest link in the transmission system has low service life.

The starting current of asynchronous motor is large, the rotor inertia is large, and there is current passing through, so it is easy to heat in the case of frequent positive and negative rotation, which will lead to insulation damage and motor failure during long-term use.

In the second generation of development process, there is also a clutch type (high energy) screw press. The flywheel driven by the motor always keeps one-way rotation, and the flywheel is separated from the screw. There is a hydraulic clutch between the flywheel and the screw. The combination or disconnection of the clutch is controlled by the hydraulic pressure. Setting the clutch engagement force is to pre select the striking ability by setting the torque that the clutch can transmit. The return stroke of the slider is driven by the hydraulic system to return to the top dead center. There are both mechanical clutch transmission and hydraulic transmission for slider return. The structure of the machine is complex and the failure rate is high.

Therefore, in the application of electric screw press for more than ten years, due to the inherent defects of these two motors and driving modes (pinion damage, motor heating and burning, flywheel tooth surface wear, etc.), the energy control accuracy is not high (the equipment capacity index CMK is about 0.8), and the stability and reliability of the equipment are not high.

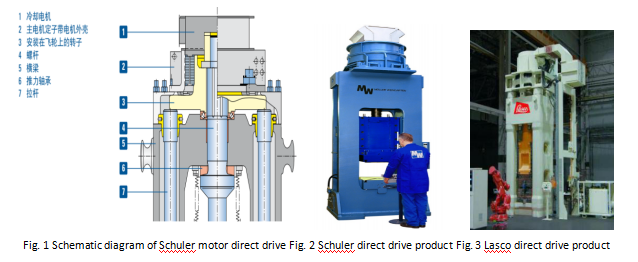

3. Servo direct drive screw press: permanent magnet synchronous servo direct drive motor is used to directly drive the screw, and the rotary motion of screw is converted into reciprocating linear motion of nut and slider.

Servo press is the latest development of forming equipment, known as "the third generation press". With the maturity and application of medium and high power AC servo motors and their drive control devices, German Schuler, Lasco, SMS and other companies have already launched commercial products. In the field of die forging, the servo direct drive screw press has the characteristics of zero transmission and zero maintenance, which overcomes the fault factors of the original transmission link of the screw press, ensures the reliability and stability of the equipment, and has epoch-making significance.

AC synchronous servo direct drive motor is used to transfer torque directly to the screw, without intermediate transmission parts, vulnerable parts and energy loss. Overcome the inherent defects of the traditional drive system, greatly improve the transmission efficiency of the system and improve the energy utilization rate. In terms of the design, reliability and reliability of the screw drive, the design and maintenance of the direct drive unit are representative.

In the selection of forging equipment, in addition to considering the strength and stiffness of the bed, the accuracy of energy control is the key factor. In forging with high quality requirements and difficult forming, the main forging equipment mostly adopts direct drive screw press, which can control energy accurately and ensure the consistency of formed products.

HUBEI LEADING SCI.&TECH CO.,LTD

address:湖北省鄂州市四海大道特1号

phone/fax:0711--3350898

email:13707107362 @ 163.com

Follow the public account

Copyright © 2015.Company name All rights reserved.More Templates